Forklift Injuries

In 2013, there were a total of 4,585 fatal work-related injuries in the United States. An estimated 100 of those fatal injuries were caused by forklifts. On top of that, there are an estimated 34,000 forklift injuries in our country each year. It’s clear that forklifts can be dangerous pieces of equipment, and when not used in the right environments with the right training, they can be harmful and deadly.

Q: What are the leading causes of forklift injuries?

• 22% due to forklift overturns

• 20% due to a victim being hit by a forklift

• 16% due to a victim being crushed by a forklift

• 9% due to the victim falling from the forklift

Q: How does a forklift injury affect your business?

A: Over 40% of forklift injuries led to an employee being absent from work, with an average of 61 days absent per injury among this group. This can result in huge losses in productivity. Placing emphasis on a safe workplace and safe operator techniques is not only the right thing to do, it is also the smart one.

Q: How can you make your workplace safer?

A: Proper training is the best way to prevent forklift accidents. However, it is not the only way to keep your workers and pedestrians safe. According to OSHA, a safe workplace is one that avoids…

• narrow, unorganized, and crowded aisles

• blockages at intersections and doors

• heavy traffic in a forklift work area

• loud noises that prevent communication and/or drown out

• dust and toxic gases that can harm the forklift

• that might obscure the forklift

• disrepair of loading docks

• any forklift load that is poorly stacked, too heavy, too large, or stacked on a pallet that may break

In addition, make sure that your forklift is regularly maintained and does not get too old to function properly. Never let your operators go too fast on the forklift, and avoid using any inappropriate on the vehicle. Finally, make sure that there is clear communication between a forklift operator and the workers and pedestrians around him. No amount of guidelines can prevent every hazardous situation, so it is critical that an operator and those around him can work together to handle these cases.

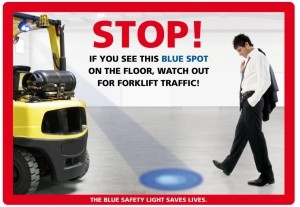

Making Your Work Area Safer

If you’re looking for specific ways to make your forklift work area safer for pedestrians, consider the following suggestions:

• use specific walkways for pedestrians in forklift traffic areas

• don’t let pedestrians enter areas in which forklifts are presently operating

• make sure the operator is aware of any pedestrians near his forklift

• sound the forklift’s at any intersection, blind corner, doorway, or entrance to a narrow aisle

• consider installing forklift mirrors

• never let pedestrians walk beneath raised forks

• avoid driving forklifts in areas or during times of high pedestrian traffic

Hopefully, with these guidelines, you, your fellow workers, and any pedestrians in your area will stay safe and aware of the dangers that come with working around forklifts. They’re essential tools for any successful industry, but that benefit shouldn’t come at the cost of workplace safety.

Check out some of our most popular safety products below, including , , horns, and our signature .