Intella Parts’ forklift forks are manufactured to meet or exceed two major specifications.

Major Specifications:

ANSI

(The American National Standards Institute) has published standard number entitled “Hook type forks and fork carriers for powered industrial fork trucks.” This standard encompasses standards relating to hook type forks up to 24,000 pound lifting capacity. Intella’s forklift forks are built to meet this standard. It’s important to note that ANSI doesn’t “approve” or “endorse” certain products–they simply publish a standard for manufacturers to adhere to. For more information on this standard, and to download and read the standard click . You may download a PDF of the standard for no charge by submitting your name and email address.

ISO2330

ISO2330

is the world standard for forklift forks. This International Standard specifies manufacturing, testing and marking requirements for solid-section fork arms, for quantity production and with all types of mounting. Here’s the main difference between ANSI B56 and ISO2330. Manufacturers “self-certify” to the ANSI B56 standard–ANSI publishes standards, they don’t approve or disapprove products that claim to be built to that standard. ISO2330, on the other hand, actually is an audited standard–if manufacturers advertise that they build forklift forks to ISO2330, they must pay for an extensive on-site audit. Once the auditors certify that the standard is met, the manufacturer receives an ISO2330 certificate.

The first ISO2330 test is a yield test. For forklift forks built to a load capacity of less than 5500 kilograms (12,100 pounds), the test load is 3 times the load capacity. For forklifts forks built to a load capacity of greater than 5500 kilograms (12,100 pounds), the test load is anywhere between 2.5 and 3 times the load capacity of the fork.

The second ISO2330 test is an impact test. In this test, cross sections of steel are removed from the forklift fork according to ISO 683-1. They are then impact tested according to ISO148 at -20 celsius.

The third ISO2330 test is a fatigue test. In this test, the sample forklift fork is load tested 1,000,000 (one million) times (!!). The load is 1.25 times the lifting capacity of the fork. The fork can’t fail, and there can be no cracks after the test.

All three of these tests are performed under the auspices of the ISO auditor. This is a major difference from the ANSI specification. You can rest assured that Intella forklift forklifts are manufactured to top international standards and suitable for any industrial forklift.

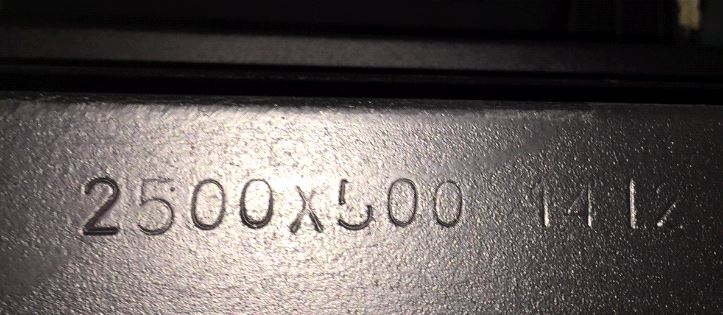

The last ISO2330 requirement is that each forklift fork is stamped on its side with the following:

– fork arm capacity in kilograms

– manufacturers designation

– date code or serial number code

SORRY Americans used to inches and pounds! Since this is a global standard, it’s all metric on the forks

Lifting Capacity

In this photo, you see 2500×500. What this means is that the fork has a lifting capacity of 2500 kilograms (5,500 pounds) at a 500 mm (20 inch) . This is the forklift fork capacity per fork not per pair. In this example, if you had two of these forks on a forklift, your forklift forks have a lifting capacity of 5,000 kilograms (11,000 pounds). This should not be confused with the lifting capacity of your forklift. Consult the on your forklift to determine the lifting capacity of your forklift.

Measuring Forklift Forks

Forklift forks are measured and ordered by knowing length, width, and height. To learn more about measuring forklift forks, check out this Youtube video:

.

Looking for forklift forks? Intella Parts Company can help!

regarding the 500 mm which represent load center,

Is it also represent blade thickness ?????

No; 2 completely different concepts/ideas. Good explanation of load center is here: https://www.osha.gov/SLTC/etools/pit/operations/loadcomposition.html

How to determine the reference for the thickness of a folding type fork?

These are the markings: 1,362 x 600 KP 96

Measure it from the bottom of fork (floor side) to the top of the fork. That dimension is considered thickness.