How to Assemble and Disassemble a Forklift Carriage

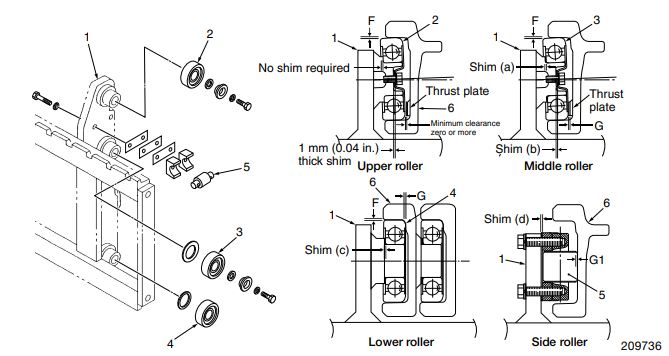

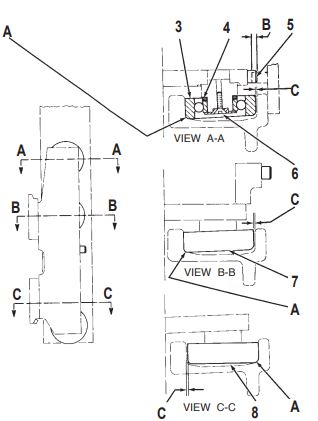

JUMP-TO LINKS: Assemble Forklift Carriage, Disassemble Forklift Carriage How To: Remove & Install Forklift Carriage To start, raise carriage (1), position a wooden block as shown, and lower carriage (1) onto the wooden block. Next, disconnect two hydarulic lines (4) from side shifter cylinder. Plug and cap all openings to prevent contamination. Then, remove four […]

Read Post