Spare Forklift Parts: What You Should Have on Hand

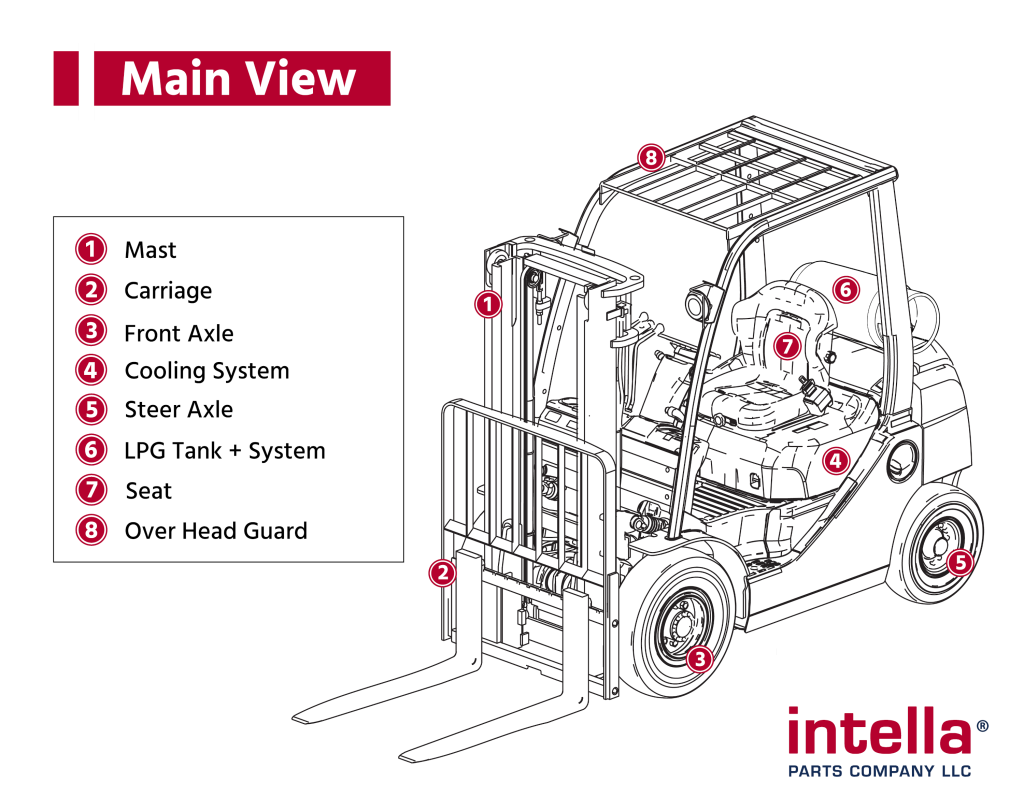

Proper maintenance and timely replacement of forklift components ensure smooth operations in warehouses and other work environments. Below, we’ll discuss what spare forklift parts you should have on hand, the importance of maintaining an inventory of these parts, and how to find dependable replacements. Identifying Forklift Parts That Can Be Replaced A standard forklift comprises […]

Read Post