.

Recognizing Modes of Failure

There are many ways that chains on forklifts can fail. It is very important to recognize the signs of these many modes of failure before they result in further damage to the forklift, its load, or its operator. Listed below are a few of these types of failures.

.

Q: What is normal chain wear?

A: This is the wear that is accounted for by the normal life of the chain and is caused by typical use of the chain. The sections of the chain that move over sprockets or sheaves (doing the greatest amount of work) should be most closely monitored for this type of wear.

.

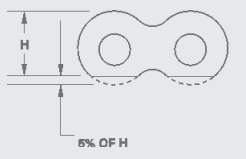

Q: What is plate edge chain wear?

A: When a chain runs over a sheave, the side that is in contact with the sheave can be worn down. This decreases the height of the plate and makes the chain asymmetrical. An example is shown to the right.

A: When a chain runs over a sheave, the side that is in contact with the sheave can be worn down. This decreases the height of the plate and makes the chain asymmetrical. An example is shown to the right.

Q: What are distorted or damaged chain plates?

A: If the plates of the chain are damaged or distorted, it can interrupt the running of the lift chain.

.

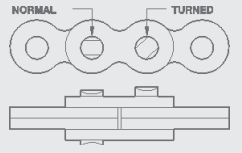

Q: What are turned or protruding forklift chain pins?

A: Forklift chains are held together by pins placed within plates. If a chain is not sufficiently lubricated or is under unusual tension, its plates can create enough friction to turn a pin. This may cause the pin to protrude from the chain, eventually screwing out of the plates and resulting in failure. An example is shown to the right.

.

Q: What is forklift chain pin head wear?

A: If a chain is not aligned correctly, the heads of the pins holding the plates of the chain together can be worn down.

.

Q: Why might a chain plate crack?

A: There are many reasons that a plate may crack. Fatigue cracking is due to the chain bearing a greater load than it is able to bear, and its cracks begin at the pin hole in the plate or perpendicular to the chain pitch line. Stress corrosion cracking is due to the chain being used in a non-ideal environment. Cracking may also be due to certain combinations of both environmental conditions and stress. An example is shown to the right.

.

Q: What is a tight forklift chain joint?

A: If a joint within a forklift chain is too tight, the chain may not rotate as freely as it should. Friction builds up in the joints of the forklift chain and speeds up the process of wear on the chain. Tight joints can be caused by bent or rusty pins and plates.

Q: What is forklift chain tensile failure?

A: Repeatedly loading a forklift chain beyond its elastic limit can cause tensile failure. This form of failure stretches and bends side plates. It also stretches the plate holes and may cause them to break. An example is shown to the right.

A: Repeatedly loading a forklift chain beyond its elastic limit can cause tensile failure. This form of failure stretches and bends side plates. It also stretches the plate holes and may cause them to break. An example is shown to the right.

.

Q: What causes enlarged chain holes?

A: Enlarged holes in the plates of the chain are likely due to misalignment of the chain. To fix this problem, replace the forklift chain and fix the misalignment. An example of enlarged holes is shown to the right.

A: Enlarged holes in the plates of the chain are likely due to misalignment of the chain. To fix this problem, replace the forklift chain and fix the misalignment. An example of enlarged holes is shown to the right.

Need to Know How to Install a Forklift Chain

Installing new forklift chain? Check out our how to video on Youtube

.

Great info Marcel-

A short course for the tech’s to carry and documentation for the user all in one printable carry with.

Thanks for the information you consistently provide.