Learning About Forklifts

Want to know about maintaining and upgrading forklifts? Intella has you covered! Here we provide resources that will help you learn all about forklifts.

Spare Forklift Parts: What You Should Have on Hand

Spare forklift parts you should have on hand, the importance of maintaining an inventory of these parts, and finding dependable replacements.

Forklift engines – Intella sells rebuilt forklift engines!

Curious what a rebuilt forklift engine costs? We have ball park costs for you and a vast array of forklift engine parts right here at Intella Parts.

Can’t Find the Problem? Tips for Troubleshooting a Forklift

We’ll help you troubleshoot issues with your forklift by helping you find the problem and offering tips for solutions.

Why You Should Buy a Forklift Instead of Renting

Can’t decide between renting or purchasing a forklift for your company? Each has its benefits, but we let you know our recommendations.

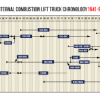

Hyster Forklift Models by Decades

We often get customers asking us how old their Hyster forklift when inquiring on Hyster forklift parts. In fact, we had a prize competition in 2023…

7 Benefits of Choosing an All-Terrain Forklift

Are all-terrain forklifts that different from typical forklifts? They are, and you can learn all the advantages of all-terrain forklifts for outdoor work here.

Zapi Error Codes

Zapi makes parts for the following forklift manufacturers: Yale, Hyster, Crown, and more. ** If after reading these PDFs you are still ‘stuck’, consider purchasing a…

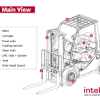

What are the parts of a forklift and their purpose?

It can be hard figuring out what is the right part number to order when you need to order forklift parts. Every day we get a…

WINNER 2023 Oldest Hyster contest

We have a winner! Phillip DeLuna from Public Steel in Amarillo TX submitted their 1945 Hyster model KD KarryKrane. We’re not affiliated with the Hyster…

Avoid injuries changing forklift tanks!

A completely full forklift propane tank weighs nearly 40 pounds! And if your facility requires operators to switch out tanks, it can be a injury waiting…

How Much Does a New Forklift Cost?

Making a decision on which forklift your company should purchase is not an easy and ephemeral one. There are multiple factors that may contribute to a…

Hyster Forklift Steer Axle Design

Hyster forklifts are one of the toughest and most beloved forklift brands on the market. One reason that Hyster forklifts are considered so reliable is that…

What Year is My Toyota Forklift? Toyota Vin Lookup

Toyota Forklift Year by Model Number Decoding forklift model numbers can be difficult to begin with and it seems as though Toyota only makes it harder….

store.Intellaliftparts.com is now intellaparts.com!

After operating as store.intellaliftparts.com for nearly 13 years, we have introduced a fresh name and website. Let’s check out our past and discover what Intella has…

Taylor Forklift Serial Number Lookup: Where Do I Find It?

Note: This page is for finding your Taylor forklift’s serial number only. To find a serial number for a forklift of a different brand, click here…

Avoiding Common Forklift Hazards

Here are some of the common hazards associated with forklifts and some ways of avoiding them.

Construction Skills: Resources for Apprentices

Most apprentice programs require applicants to have a high school diploma or GED certificate. A worker is usuall….

7 Different Types of Forklifts | Common Classes of Forklift Trucks

Forklift trucks come in a number of different sizes and models. In this article we will discuss the differently ….

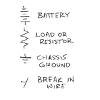

Electric Forklift Tips and Tricks

Start here before working on an electric forklift to learn some handing tips and tricks.

Electrical Contactors

Learn how to identify and replace electrical contactors

Forklift Battery Maintenance

Forklifts may use several different types of batteries. It’s important to care for your battery to ensure you a ….

Forklift Blocking Instructions

Equipment blocking procedures prior to performing repairs under a forklift.

Forklift Buying Guide

Looking to buy a used forklift truck? If you are, here are basic things you need to consider!

Forklift Truck Safety

The forklift truck has become the workhorse of modern warehousing operations. They allow us to move substantial ….

Forklift Won’t Start? How to Start a Forklift

Your forklift won’t start. The shipment has arrived at your dock with your raw materials for the hot job.

Hyster and Yale IFAK Tool

You’ve watched the technician from the Hyster or Yale dealership using his laptop computer and the Ifak cable ….

Proper Maintenance of Forklift Engines

Performing maintenance on forklifts and their different parts is absolutely vital.

Replacing blown fuses on electric forklifts

Electric forklift stopped working? Could it be a fuse? Learn more

Shorted or open circuits

Learn the difference between an open electrical circuit and a shorted circuit

Understanding Electrical Diagnostics

So your forklift won’t move, where do I start? The problem could be your electrical system.

Forklift Tire Replacement | When To Change Tires

Forklift tires come in many different sizes and tread patterns to meet the needs of different equipment and envi ….

History of The Fork Truck

The fork truck, which later evolved into the forklift, has been in use for over 80 years. No one is quite certai ….

Forklift Safety

Forklifts or lift trucks are used by numerous industries. Moving materials, raising, lowering and removing large ….

How to Select a Forklift Battery Charger

Selecting a forklift battery charger is easy if you know what to look for. Read our “How to Select a Forklift Bat ….

Where to find forklift serial numbers

Learn where to find a serial number on a forklift.

Forklift Seatbelt Safety

Seatbelts are important safety devices that were designed to secure vehicle occupants against the harmful moveme ….

Forklift Tire Replacement | When To Change Tires

The tires of your forklift have a difficult life. They are required to traverse some rough terrain on your works ….

How To: Performing Basic Maintenance on a Forklift

Forklifts are some of the most reliable and rugged machines used in many different industries; and a crucial fac ….

Tips for Preventing Forklift Accidents

The need to optimize a company’s productivity combined with uncontrolled traffic and complex machinery, are all ….

Forklifts: Cold Weather Operations and Safety Guide

Heavy machinery like forklifts require constant care and precautions even in the best weather conditions.

10 Free Forklift Simulator Apps You Didn’t Know Existed!

There are simulation games for all types of activities such as flying, boating, fishing, and even driving a fork ….

Glossary of Forklift Terminology

We’ve compiled a list of all the top forklift terminology into one easy-to-understand article.

Commonly Replaced Forklift Parts

These forklift parts are some of the most commonly replaced on any model of forklift, and as an owner or operato ….

How do battery chargers work?

Good battery chargers provide the base for durable well-performing batteries.

How To Dispose Of Batteries The Proper Way | 4 Facts You Should Know

Throwing away batteries may seem harmless, but can have dire effects on the environment.

Wheel Separation Causes in Heavy Vehicles & How to Prevent Them

Imagine driving a massive 16-wheeler truck barreling down a clear, steep road. Suddenly ….

No Start – Engine Cranks Over

The engine cranks over but does not start. What do I check first? Well I am going to start out by saying that yo ….

Forklift Parts Inventory Best Practices

Looking for forklift parts inventory best practices? Here are the best practices of forklift inventory optimizat ….

Canadian Forklift Guide

There aren’t many forklift manufacturers that produce every type of forklift model available in the market. If ….

Forklift Troubleshooting | Common Forklift Problems & How To Fix Them

Looking for a troubleshooting guide for your forklift? Looking for the proper part to get that forklift engine r ….

Guide to Supply Chain Management

It doesn’t matter what you sell – if you have a product you’re supplying to a customer, there’s a good chance yo ….

“WHO” Forklift FAQs

It’s not entirely clear who first created the forklift, but the Clark Company is usually credited with inventing ….

5 Most Important Parts of a Forklift

Here are the 5 most important forklift parts that specialize in the safe operation of the machinery.

Frequently Asked Questions (FAQs) About Forklifts

Have questions about Forklifts? Here are the frequently asked questions (faqs) about forklifts with answers from ….

FAQ – Can

Can a forklift drive on the road? Can a forklift carry passengers? Can forklift batteries explode? Can a forklift ….

History of The Wheel

Imagine a world without wheels. We would have to find an alternative way to drive our vehicles around, our steer ….

Forklift Load Center | What Is It Used For? | Capacity & Attachments

If you work with forklifts, you should be familiar with the concept of load center distance.

Poor Quality Propane and Forklifts

There is a perception that propane quality has diminished over the years causing increased issues with the fuel ….

About Timing Belts and Interference Engines

A timing belt is a belt made of rubber and other materials including polyurethane reinforced with polyester, fib ….

Forklift Parts Repurposed to Build an Electric Motorcycle

What do you think of when you think of an eco-friendly electric vehicle?

FAQ – Will Not

What to do when your forklift will not……

Forklift Blue Safety Lights Importance | Why We Need These Lights

Each year forklifts account for almost 100,000 industrial accidents, about 1% of the accidents in the workplace.

How To Fix Forklift Brakes

This tutorial walks you through a typical forklift brake job.

How to rebuild Impco model J regulator

You will see in the tutorial below that rebuilding a model J is pretty simple.

The most common forklift service call

One of the most common forklift complaints from forklift operators is a noticeable propane gas smell around the forklift.

How to replace a forklift master cylinder

This tutorial will show the replacement of a master cylinder on a Hyster 5000 pound forklift.

How to fix forklift steer axle

In this tutorial you’ll see how to replace some of the most common wear items.

How to fix Aisan fuel regulator

Rebuilding an Aisan regulator is a bit more difficult than the traditional and popular Impco model J.

How to replace a Toyota forklift seat

It’s super easy to replace a seat yourself, all you need are a socket set and a little mechanical ability.

How to fix Clark forklift brakes

An easy guide to changing Clark forklift brakes.

5 Forklift Seat Belt Tips

Learn the five most important forklift seat belt tips.

6 Daily Forklift Checks To Ensure Optimal Function

Learn how to keep your forklift functioning as it should.

5 Forklift Hazards Due to Bald Tires

Learn how to avoid bald forklift tires on your forklift.

Lithium Ion Batteries vs. Lead Acid Batteries: Which is Better?

The influx of lithium ion batteries and how they hold up against lead acid forklift batteries. We’ll explain the pros and cons of each.

How To Rebuild A Hydraulic Cylinder

How to rebuild a hydraulic cylinder, how much it’ll cost, and what’s needed to get the job done

Hi,

We need Hyundai forklift parts

Great send us an email at [email protected]